Looking to make a customized toy for your pinball machine? We got you covered with the DIY Injection Molding process and what you’d need!

Injection Molding DIY & Process

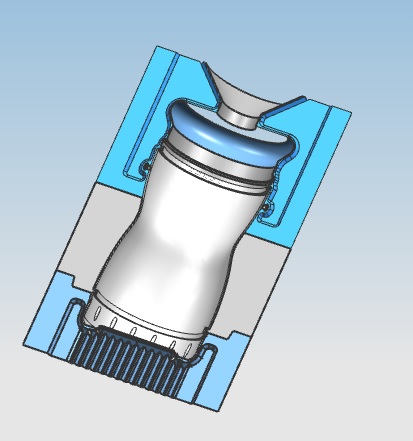

What Is Injection Molding?

It a process used for manufacturing a wide variety of items from small components to large ones. It uses a granular plastic that is gravity fed from a hopper, forced into a heated chamber by a screw-type plunger, melted, and then pressed against the mold. It then cools and is removed as a solid part. Rapid injection molding uses aluminum molds that are quick to make, while large-scale production typically uses steel molds.

Injection fabrication makes it possible to produce parts in large volumes. This is why it is typically used in mass-production processes, where thousands or even millions of parts are needed. The biggest drawback, really, is that the tooling time and costs required to set up for the molding process make the technique inappropriate for small batch production runs (luckily we have 3D printing for that now).

What You Need for DIY Injection Molding

Building a setup for DIY injection molding does require some investment. It takes both money and time to acquire the right equipment and to master using it. However, these costs are in many cases still lower than the cost of a single metal mold, so the eventual time and cost savings, once you’re up and running, will easily offset the initial effort. source.

Here’s what you’ll need to get started:

- A high-performance desktop SLA 3D printer, like the Formlabs’ Form 3. The Form 3 can produce accurate molds with crisp features, and a smooth surface finish that will yield high-quality final molded parts. Beyond DIY injection molding, an SLA 3D printer is also a valuable asset for prototyping and other applications throughout product development.

- A 3D printing material that can withstand the temperature and pressure on the mold during the injection molding process. We recommend the following materials for Formlabs SLA 3D printers:

- Rigid 10K Resin is an industrial-grade, highly glass-filled material, which provides a solution that can cope with a wider variety of geometries and injection molding processes. It has an HDT of 218°C @ 0.45 MPa and a tensile modulus of 10,000 MPa, making it strong, extremely stiff, and thermally stable.

- High Temp Resin offers a heat deflection temperature is 238 °C @ 0.45 MPa that is suitable for injection molding. This material is more brittle, but is recommended for materials with a high molding temperature and to reduce cooling time.

- Grey Pro Resin has a lower thermal conductivity than High Temp Resin or Rigid Resin, which leads to a longer cooling time, but it is softer and can wear hundreds of cycles.

- A benchtop injection-molding machine, such as the Galomb Model-B100 or the Holipress. There are a number of benchtop injection molders on the market that vary in cost. Many of the lower cost molders use a hand-driven plunger, while some of the more expensive units use a screw or pneumatic system. Some of our customers have recommended systems from Minijector, Morgan, APSX, or Micromolder as well. Desktop automated molders such as the product line from Babyplast are good alternatives for mass production of small parts.

- Plastic pellets of your choice

- A CAD software tool of your preference to design the mold insert, such as Blender, which you can download for free

The injection molding process cycle follows 4 stages and typically takes between two seconds and two minutes per part

-

Clamping

This is the part where two halves of the molds are securely closed by the clamping unit. Hydraulic power is used to keep the clamping unit in place while the specific material is injected (typically a thermoplastic).

-

Injection

At this stage, raw plastic material or pellets are fed into the injection molding machine, pushed into the injection unit, melted and then injected into the mold.

-

Cooling

Cooling allows the molten plastic to solidify and take the shape of the mold. There are specific cooling times for different parts and components, depending on the maximum wall thickness of the part and the thermodynamic properties of the plastic material

-

Ejection

An ejection system is used to push the molded part out of the clamping unit. A mold release agent may be sprayed onto the surface of the mold cavity before injection to facilitate easy ejection and prevent damage to the new part.

What are the benefits of injection molding?

Low production costs

In injection molded manufacturing, the price per unit is extremely low. The most significant costs are the setup costs. As more parts are produced, the price tends to drop drastically. Once the initial costs of fabrication have been paid, the profit margin can be quite wide. This makes financial sense in the business front, so long as there is a demand to satisfy the production.

Low scrap rates

Unlike traditional manufacturing processes, where a substantial percentage of an original block or sheet is cut away during production, injection molding cuts with accuracy and waste plastic usually come from overflow material that leaks out of the cavity. It can also come from runners, sprue, and gate locations.

Repeatable and consistent

As a process used in high-volume production, injection molding is ideal for producing practically identical parts. Each part produced is going to be the same as the first one, which is important for consistency and reliability.

Of course, injection molding is not perfect. But its benefits often outweigh the disadvantages.

A major challenge in injection molding is designing a mold. The main focus is usually on the finished products, but no part would be made without the mold from which it is formed. The design aspect of a component is often overlooked, but it is the most important.

Thanks for reading

Injection Molding DIY & Process

PINBALL ADVENTURES

Pinball Adventures is a North American manufacturing company producing fresh and unique Pinball machines. Our goal is to create to the highest standards, and spark the same joy we found as gamers when we rolled our first quarter into that coin slot so many years ago. Stemming from a lifelong passion, Pinball Adventures is created by gamers, for gamers. We strive to bring high quality, innovative, and captivating experiences for all to enjoy.

Visit our website at pinballadventures.com and also check out our new Instagram page for more updates https://www.instagram.com/pinballadventures/

Pinball, Pinball Adventures, Pinball Buzz, Pinball, Pinside, History of Pinball, Pinball News, Pinball Updates, Origin of Pinball, Pinball Skill Shots, Pinball Canada, Vancouver Pinball, pinball relates to real life, collect pinball, shooter rods, Parts of a pinball machine, Move a pinball machine, most expensive pinball machine, guide to playing pinball, Largest Pinball Collection, hardest pinball game, 5 Classic Pinball Machines, Owning a pinball machine, 5 Cool Pinball Art From The 80’s , New Led Zeppelin Pinball, 3 Greatest Older Pinball Machines